Welcome to Air Bearing Solutions

Your engineering and air bearing partner. With over 35 years experience in the air bearing industry we are in a unique position to provide your business with extensive expertise in the air bearing design, manufacture, assembly, balancing, installation, service and repair.

We have the capability to tailor our services to whatever needs your business may have, including assistance with air bearing design, mechanical design, the design and production of prototypes and the provision of training for your personnel. Whatever your requirement we aim to help.

What we offer

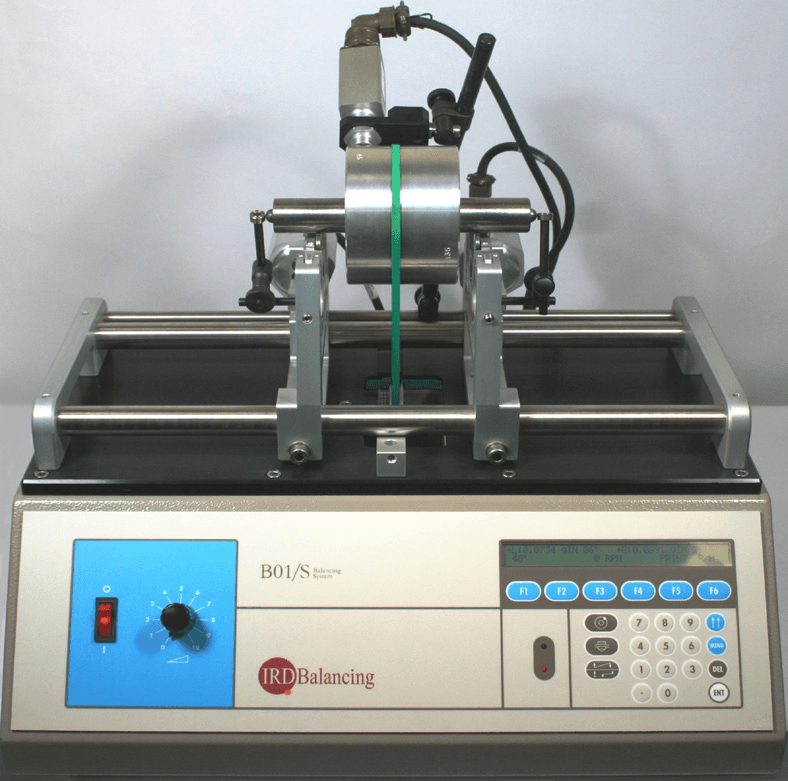

Dynamic Balancing Service

Shafts, rotors, fans and assemblies – either self powered up to 15kg or independently driven up to 8kg. Larger units can be handled by prior arrangement.

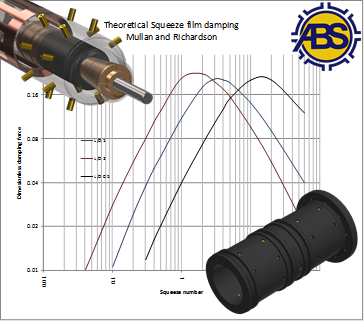

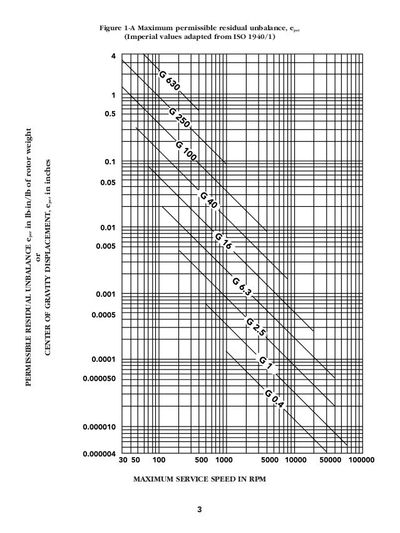

Primarily a specialist in ultra-high speed air bearing shafts running >300,000 rpm but can easily accommodate other applications. The air bearing technology requires the most demanding of vibration control of any industry but we can provide guaranteed residual imbalances to any level required. Residual imbalance down to G0.4

Balancing reduces the vibration and noise in a system and will prolong bearing life and improve accuracy. Faster rotational speeds can be achieved and we have specialist techniques for improving dynamic rotational accuracy down to 1 micron in an air bearing.

In addition to the balancing service we have full design and engineering capabilities, which enable us to provide the best technical partnerships. We are happy to discuss any vibration problems / requirements and offer reliable, unbiased advice if required.

Precision Manufacturing

We can take on complete complex projects – offering design or production engineering improvements and entire project management or offer nut and bolt assembly service from plans.

Our plant has precision centre lathe, CNC & manual universal milling machines, precision dynamic balancing machine, ultrasonic cleaning and clean room area (99.998% filtration). In conjunction we have local partnerships for high precision grinding, honing and advanced surface treatments.

Air Bearing Solutions was initially formed in 2008 by Hugh Joseph after 28 years’ experience in precision engineering starting as a fully indentured toolmaker gaining expertise in plastic injection mould making, high pressure hydraulic and pneumatic valves pumps and systems and principally the design, manufacture and application of air bearing systems – ultra-precision mechanical engineering.

Turbocharger Repair

We offer a complete turbocharger repair service at a fixed price plus parts.

Units will be stripped down and thoroughly evaluated before quoting for any parts required – evaluation is not chargeable.

WE DO NOT RECONDITION – FIT OVERSIZE / UNDERSIZE NON STANDARD PARTS - WE REPAIR. Which is not only cost effective but ensures the incredibly tight tolerances required are maintained – machining to 0.001mm tolerances would treble the cost if done correctly.We only use OEM standard parts and can even offer complete brand new cores for less than the sum of the individual parts for basically a brand new turbo. We concentrate on the mechanical specifications and don't paint parts to make them look shiney.

Intermittent faults on diesel engines - like going into limp mode are often a good indication that the VNT (Variable Nozzle) is carboned up and can be rectified by cleaning and dressing the nozzles which is significantly more cost effective than replacing the turbocharger.

All makes models and sizes catered for – passenger vehicles, large commercials, marine or generators.

Parts normally arrive the day following order so we hope to have a total turnaround time of less than two days, plus collection and return shipping time. We offer a secure courier pickup and return service.

What we think sets us apart is that we are mechanical engineers, with over 20 years’ individual experience in high precision aerostatic and aerodynamic air bearing systems, and are very familiar with the hydrodynamic technology in turbo’s.

Using our ultra-precision dynamic balancing machine we can achieve balance grade of G0.4 with residual imbalance down to 0.002g.mm – which is typically a tenth of the tolerance normally applied to turbo’s.

paragraph